In 2004, a study was conducted to determine the necessary output of an Automated Storage and Retrieval System (AS/RS) to pick a specific selection of goods in cradles. The results indicated a requirement of 90 lines or 78 bins per hour. Van Marcke has occasionally pursued a policy of using second-hand systems when acquiring capital goods. They found a suitable option involving a combination of three Demag cranes and three CGP cranes.

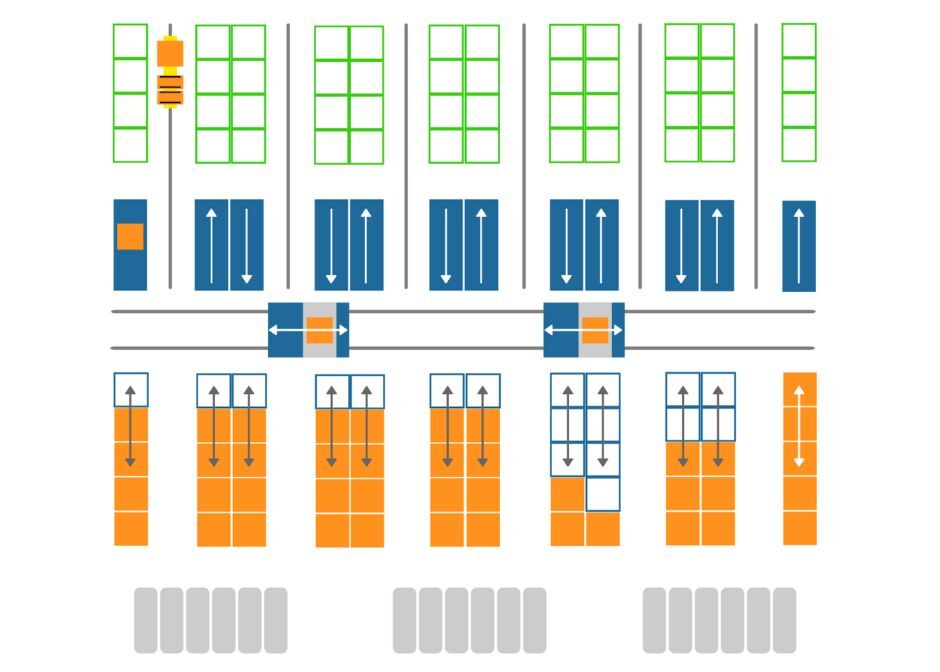

These six cranes serve two shuttles on a single track, which in turn supply the six picking stations with pallets. From these picking stations, items are picked from the bins and placed into gray containers, which are then transported away using a train system.

In 2012, the demand for a specific selection of products had increased by 60%. Therefore, the question arose whether the output of the warehouse could be optimized in line with this increase. Completely replacing the system was not an option.

The objective of the study was fourfold:

- Analysis of the Current System: The first phase involved a comprehensive analysis of the system as it was operating at that time. All aspects of warehouse operations were quantified, including crane movements, shuttles, and logistics. New warehouse layouts were then developed, with special attention given to recovering existing resources.

- Cost-Benefit Estimation: In the second phase, a cost-benefit estimation of these new concepts was performed.

- Detailed Model Development: The third phase focused on elaborating the best-performing model in detail. The development of the return on investment (ROI) was based on the quantified values from this model.

- Transition Planning: Finally, a plan was created to ensure a smooth transition to the new system. It was crucial that the continuity of article delivery was maintained throughout the transition process, without any interruptions.

RESULTS

For the analysis of the cranes, a proprietary simulation package was used to test various theories and optimization techniques, such as optimization of travel and lift speeds, zoning, condensation, consolidation, repick buffering, and double forks, all in accordance with the applicable FEM 9.851 standard.

It became clear very early in the analysis process that the shuttles were the bottleneck of the current system. To make informed decisions based not only on visual observations but also on numerical data, various simulations were conducted using the simulation package. It quickly became evident that the best-performing models were those that eliminated the shuttles from the goods flow.

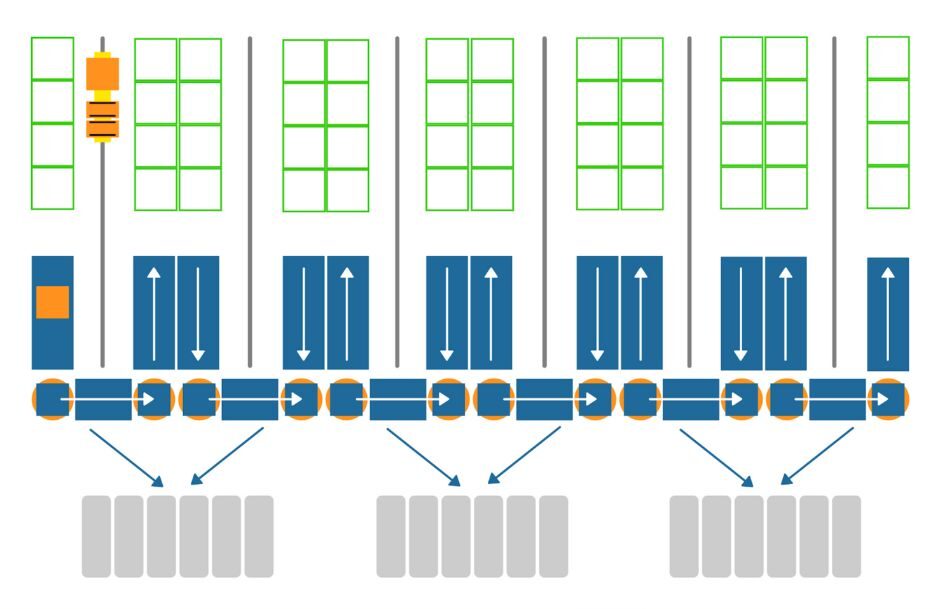

The picking setup was completely redesigned. The pickers could now pick at the ends of the cranes, which freed up a significant amount of picking space. The picker picks from a bin and then moves to the next crane to pick again. Two configurations were possible: one with 2 pickers over 3 cranes and another with 3 pickers over 2 cranes.

Additionally, replacing the mobile terminals with a “pick-to-light” system had a positive impact on pick times. The picker is optimally guided by light signals and only needs to press a button to confirm their actions.

The bins were also adjusted to allow for quicker opening and closing. A new type of bin was introduced that was much lower and had no lid, which saved additional time.

Furthermore, research was conducted regarding the pick and batch factor. A distinction is made between the number of products being picked and the number of bins that need to be offered to the picker. If multiple items are stored in some warehouse locations and/or multiple orders are being fulfilled simultaneously, fewer bins need to be provided than there are products being picked. The ratio between these factors constitutes the product of the pick and batch factor.

Using supervisory control and data acquisition (SCADA), the required data was collected to investigate these factors in the current system. The influence of bundled orders on the pick and batch factor was also graphically represented. Through a redistribution of the bins, the pick and batch factor could be significantly improved.

With the same measurements, the discrepancy in crane occupancy was also mapped out, as it had a significant impact on the success of the entire concept. A low discrepancy means that the cranes are occupied similarly. The discrepancy was introduced because the 1st and 6th cranes could only be served by a single shuttle and therefore operated more slowly.

The first three cranes were equipped for double-long bins. In the new concept, this type of bin was no longer useful. The double-long bin system was replaced with a double-transport system for single bins. The double forks were retained, but the forks were used separately, allowing for two bins to be picked up and set down simultaneously instead of one bin as before.

In the WMS system, which had to be rewritten due to the absence of shuttles, several new optimization methods were added, such as condensation, repick buffering, related goods, and consolidation and fragmentation picking.

For instance, in repick buffering, bins that are needed the same day are placed at the front of the shelves. Bins that need to be picked consecutively are placed next to each other, allowing both to be picked up and set down at the same time.

Conclusion

The result of this study is a completely redesigned model of the picking setup in the outbound zone. A lot of attention was paid to reusing existing capital assets.

In the new model, it was ensured that it was possible to handle more bins per hour and that the pickers could work faster.

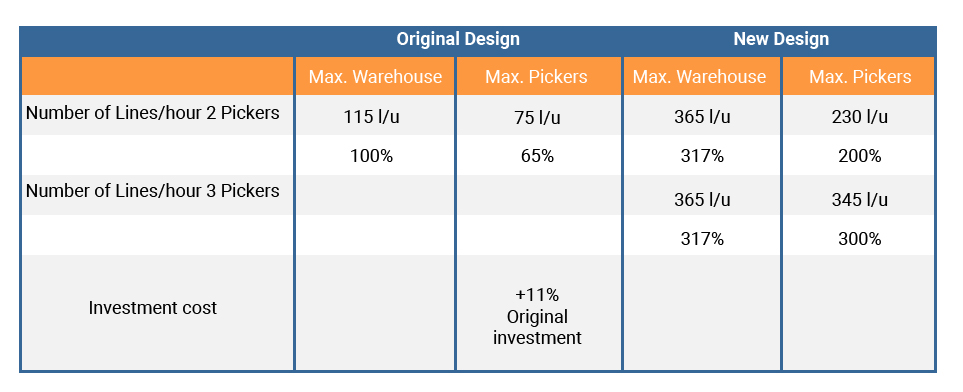

In the old system, the pickers could together manage about 75 lines per hour, but the system had a maximum capacity of approximately 115 lines per hour. The new system could handle about 365 lines per hour, but it was decided to operate with two pickers instead of three; only on busy days could the operation switch to three pickers. Each picker could nominally pick about 115 lines per hour, which is much faster than before, allowing for a total of approximately 230 lines per hour— a significant improvement.

As the study shows, a spectacular increase in efficiency can be expected with minimal investments and optimal use of the deployed resources. Contact the QWIX Europe team today to find out how we can help you get the competitive edge for your operation.

Recent Comments