As part of their ongoing growth, a frozen food wholesaler decided to build a semi-automated warehouse.

Since space was limited near the docks, the available area had to be optimized as much as possible. Additionally, in a freezer, every extra cubic meter is costly, both in terms of investment and monthly expenses. Therefore, a freezer warehouse must be as compact as possible.

Moreover, during construction, it had to be certain that the required output could be achieved. The output needed to be maximized.

To operate as compactly as possible in a warehouse, mobile racks were the obvious choice. These are racks mounted on wheels that can move sideways. They are positioned almost directly next to each other, except for one pair of racks separated by an aisle.

By moving the racks, the desired aisle can be freed to retrieve or store goods. All racks together with one aisle form a block. Two factors are important in this system:

- The larger the block, the greater the capacity of the warehouse, as fewer aisles are needed.

- The smaller the block, the more flexible the aisles, and thus the greater the input and output capacity.

The basic requirements were:

- A wide variety of item numbers and types of packaging.

- The ability to load four trucks per hour, with these trucks often arriving without prior notice. It was not possible to pre-buffer pallets as they would thaw. Trucks also had to be fully loaded within half an hour.

- The docks were paired, with one dock used for loading the truck, and the other allowing the truck to prepare for departure or the next truck to position itself. Once a truck was loaded, operations would switch to the other dock.

- To ensure fast loading, forklifts were equipped with double forks.

- For ship loading, a shuttle transport system was set up where trucks were continuously loaded at the warehouse and unloaded at the ships. A shuttle had to be loaded within half an hour to maintain a continuous process.

- Within 20 minutes of a truck’s arrival, sufficient goods had to be available at the loading docks to ensure continuous loading.

- There was one conveyor belt to bring in goods and one conveyor belt to remove goods, with one mounted above the other. Pallets were placed sequentially on the conveyor, and those not being loaded could not block the belt.

- A pallet could only stay at the dock for a maximum of one hour to avoid thawing; after one hour, the pallet had to return to the warehouse.

- There had to be as few blocks as possible to optimize space.

- The number of forklift drivers had to be minimized to avoid hindering each other.

- The logic behind the mobile racks had to ensure that there were no delays in opening the racks.

The questions that needed to be resolved were:

-

How many blocks with mobile racks are required?

This determines the balance between warehouse capacity and the flexibility needed for input/output operations. -

What can be done to load the trucks quickly enough?

This involves optimizing loading processes and possibly introducing systems like shuttle transport, as well as ensuring that forklifts and other equipment are efficiently utilized. -

What is the required buffer capacity and the speed of the buffer conveyors?

A larger buffer capacity provides a greater safety margin during loading, but it also reduces the maneuvering space for forklift drivers. -

How many forklifts need to be deployed?

This involves determining the optimal number of forklifts to balance between loading speed and avoiding congestion. -

What is the margin for the largest/smallest variety of products?

This affects how flexible the warehouse must be in handling different item types and packaging. -

What is the impact of each storage/picking algorithm? Is there still sufficient margin with a wide variety of products?

This question seeks to understand how different algorithms for storing and retrieving goods affect the overall efficiency of the warehouse and whether the system can handle high product variability without causing delays.

Simulation software does the necessary work

This could hardly be calculated by hand anymore, which is why we made use of a simulator and an emulator.

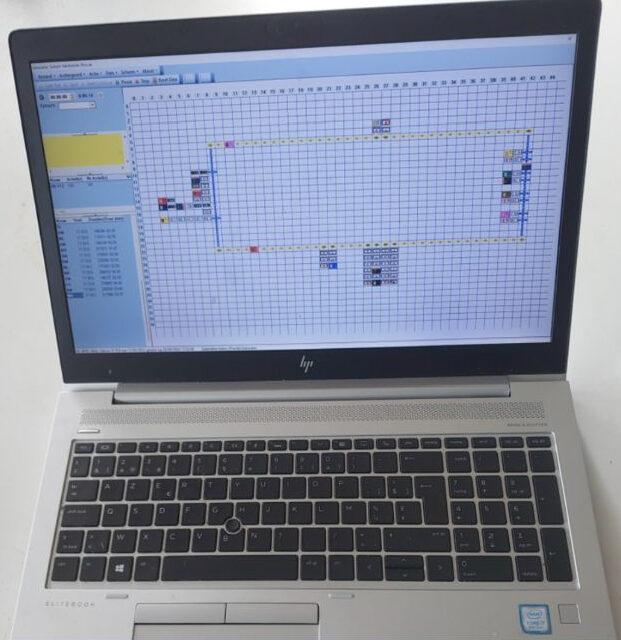

With the simulator, we simulated the installation in real-time. The software allows for various solutions and production flows to be input, including speed and cycle parameters for different machines, as well as diverse inputs and outputs. Their efficiency and yield are then calculated based on the simulated movements, which are executed randomly, mimicking real-life scenarios.

The simulation works in real-time and is visualized on the screen. This enables engineers to confirm calculations and quickly identify any limitations.

Based on the simulation, several parameters were adjusted; for instance, it was determined that the number of buffer spaces on the input conveyor was insufficient.

To thoroughly test the system, we ran the simulator for weeks to ensure that no problems would arise.

Additionally, we calculated the optimal WMS performance using the emulator. An emulator reads the stock at a given moment and a list of all incoming and outgoing goods over a year. This allows us to examine which parameters impact warehouse performance. A set of defined parameters is referred to as a model.

The software executes all warehouse movements (both picking and putting away) and determines which model performs best.

First, we established the KPIs (Key Performance Indicators). A KPI is a cost price indicator, meaning an output parameter that indicates the performance of a warehouse. Examples include:

- Stockout (total/min/max): The extent to which something cannot be picked because it has not yet been put away. If the inbound and outbound movements are not synchronized, a pallet may need to be picked while it is still on the dock.

- Incubation time (average/min/max): The average time between the request and the execution of an order. This time increases as the number of pending orders rises. This can be reduced by better combining orders.

- Buffer time (average/min/max): The average time a pallet remains in the buffer before it is loaded. If this time is too short, loading cannot occur quickly enough; if too long, the pallet may thaw.

- Discrepancy (average/min/max): The degree to which pickers are unevenly loaded. Ideally, with three pickers, each should receive and execute about 33% of the orders.

In the software, we create a set of specific input parameters and various possible picking and putting-away algorithms. Possible putting-away/picking algorithms include batch picking, condensation, FIFO (First In, First Out), strict FIFO, and speed adjustments. This set is referred to as a model.

The software then calculates the entire year for each model and displays the results at the end. This can be analyzed, as some models may show a better average but also have unacceptable minimum or maximum values.

Result

After our analysis, manual calculations, and software simulations, we compiled our findings and recommendations into a clear report that included:

- An overview of all limitations and risks of the proposed system.

- A technical dossier containing descriptions of:

- Algorithms to be used.

- Routes to be implemented.

- Outputs from all elements of the system.

- Expected performance with 2, 3, and 4 pickers.

Recent Comments